Sonoform

Speziell für Schalungsarbeiten entwickelten Materialen

Die vielen Vorteile von Sonoboard

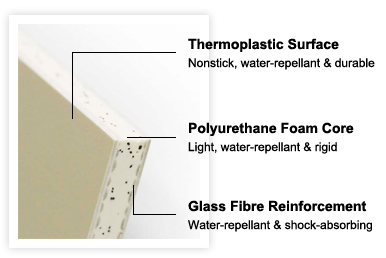

Die Antihaft-Oberfläche aus Thermoplast von Sonoboard schafft ein unerreichtes A-Klasse-Finish. Die Porenfreie Sonoboardoberfläche gibt ein super glattes Betonbild ohne Ripplings wieder. Dank der Sandwichbauweise bietet Sonoboard eine erstklassige Steifigkeit und ist leicht in jeden Rahmen einsetzbar. Das Material absorbiert kein Wasser und bleibt Lichtstabil. Das Material erlaubt eine Reinigung mit dem Hochdruckreiniger (500bar). Probleme wie quellen und schrumpfen gehören der Vergangenheit an!

Einfache Handhabung, einfache Reinigung!

Leichte, Hochdruckreinigung. Sonoboard ist ein getestetes Produkt. Keine Beeinträchtigung bei der Lagerung durch die Witterung und Sonneneinstrahlung. Geliefert wir die Sonoboard-Schalhaut auf Kundenmass ohne Verschnitt kosten.

Leichtes Reparieren, selbstheilend

STANDARD WERKZEUG UND METHODEN. Keine speziellen Werkzeuge oder Ausbildung erforderlich.

Sandwichbauweise

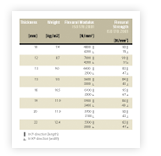

Sonoboard ist so entwickelt, das es die gleiche Stärke wie Plywood in der selben Dicke hat. Dank der Wasserunempfindlichkeit besteht die Biegefestigkeit über Jahre hinweg, für immer.

Die Glasfaserverstärkung wird auf die gewünschte Richtung vorgespannt und zugeschnitten, so das Sie die Maximale Biegefestigkeit im Panel beim Betonieren haben.

Dank der Sandwichbauweise ist das Gewicht des Sonoboard-Schalhaut geringer als jede andere Schaltafel, für spezielle Kunden Spezifikationen besteht die Möglichkeit das Gewicht herab zu setzen.

Die Modulare Bauweise ermöglicht eine hohe Flexibilität, auch die UV-Beständige Thermoplastische Oberfläche ist farblich flexibel. Warum machen Sie nicht Ihr Schalungssystem zur größten Reklametafel auf der Baustelle!

Einfach zu reparieren

Die Sonoboard-Schalhaut ist sehr einfach zu reparieren, die Schalhaut kann ohne Rissbildung genagelt werden. Die Nagellöcher verschließen sich bei der nächsten Betonierung selber mit Beton.

Mehrere Möglichkeiten der Reparatur